The Bing 64 carburetors on the 912ULS use atmospheric pressure sensing to control a diaphragm that moves a needle within a jet to adjust for rich or lean. The vent tube that comes off the carburetor bowl needs to sense the same atmospheric pressure that is at the air cleaner intake of the carburetor. Rotax designed an air box that connects both carburetors and has ports for the vent tubes. Since we don’t use the airbox on the RV-12 the vent lines are placed under the float bail wires and terminated.

With all the wierd air flows possible inside the cowl I suspected that these vent tubes were sensing everything but stable air pressure. I put pressure sensors at the ends of both vent tubes and went flying. I was not surprised to see the pressures at both tubes varying and almost always different from each other. This meant the carburetors were being adjusted rich and lean throughout the flight.

THE FIX:

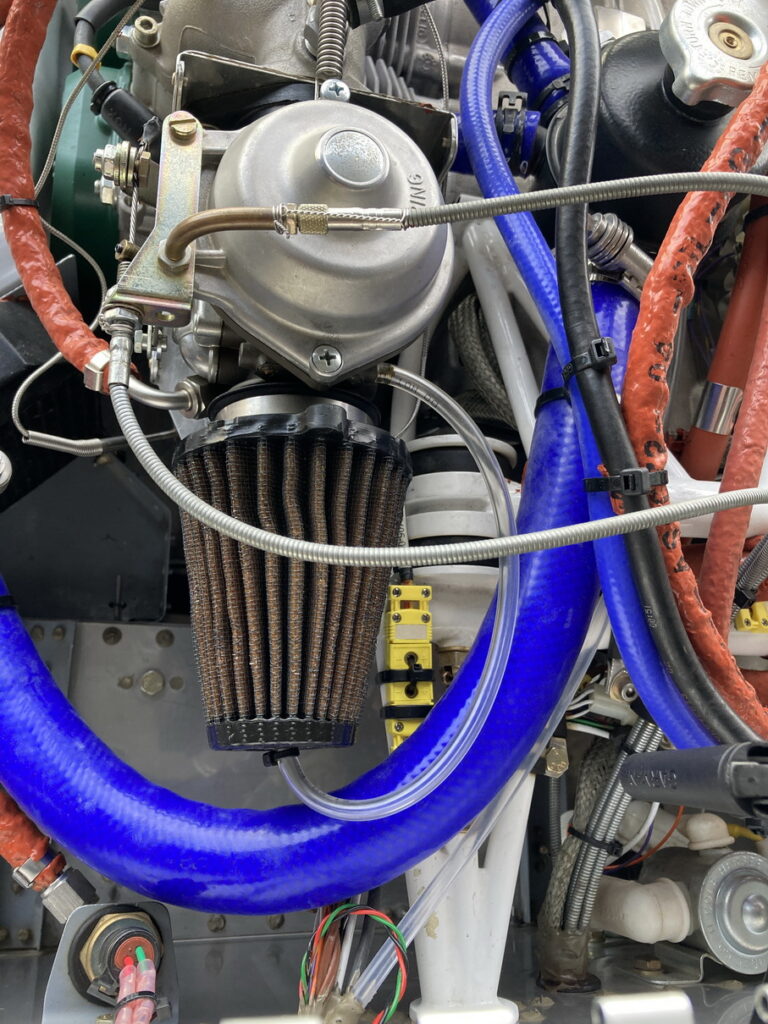

I used longer Tygon F-4040-A tubes and put them through the back of their respective air cleaners. I inserted a piece of 1/8″ stainless tubing bent to 90 degrees for the turn at the back of the air cleaner and a solid area so I could add a zip tie without crushing the tubing.. The zip tie is used to prevent the vent tube from going to far into the air cleaner. I melted the end of the tube and put 4 side holes with a hot wire for venting.