I live and fly a lot in So Cal where the summer temps hit 110f, I don’t let the temperature stop me from flying but the Rotax does complain, oil temps will hit 245f on days when the air temp is over 80f in a continuous climb.

Obviously step climbing or lowering RPM will reduce the temps but……………….

I looked for a way that I could maintain 220f or less oil temperature regardless of the outside temperature or demands I put on the engine. My muffler is already spaced 1 ½ inches from the oil cooler via a lower cowl mod.

First I tried different prop pitches, no significant improvement. Next I tried shielding the oil cooler from the radiant heat of the muffler, that seemed to help a few degrees, but not the improvement I was looking for. I placed a baffled in the front plenum to divert some coolant radiator air to the oil cooler, this gave hotter coolant but didn’t improve the oil temps. I opened the rear of the cowl by 20% where the air exits using spacers under the cowl screws, no improvement. I created a ram air intake of approximately 8 square inches using the oil cooler door, no improvement.

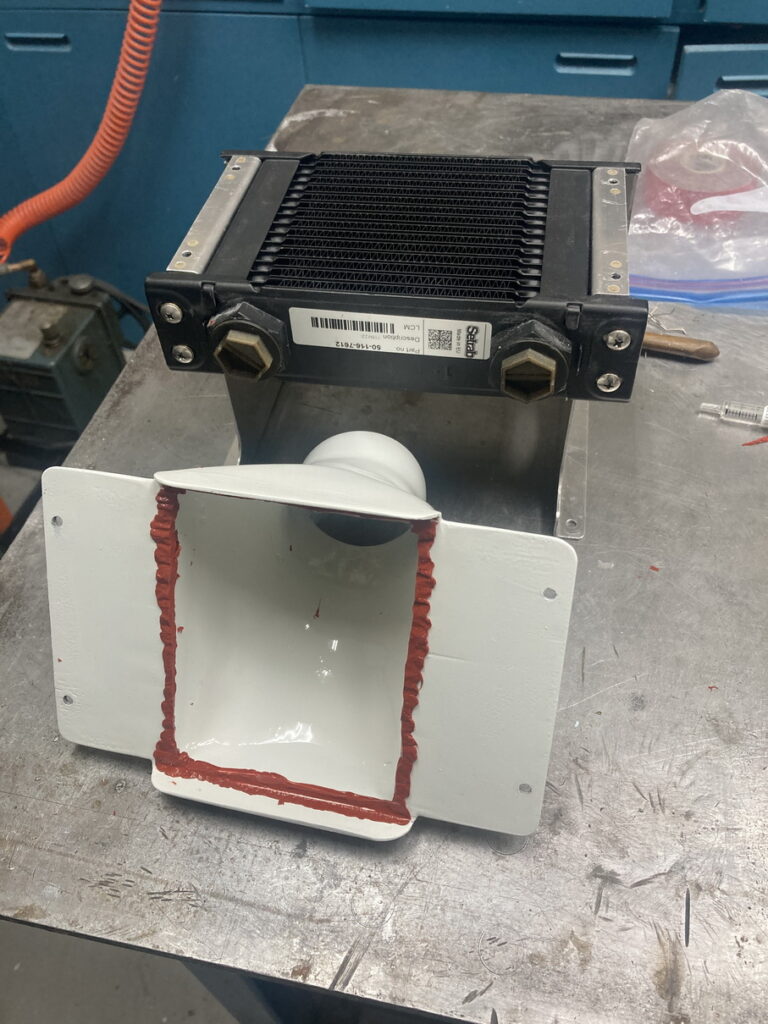

My final idea was to add a second oil cooler. After a long search I decided on a Setrab 50-116-7612 oil cooler. It has a frontal area of approximately 4” square and is 2” thick with 16 rows. It has roughly the same total surface area as the OEM cooler. I plumbed it in series with the OEM cooler. Aircraft Specialty Flightlines, was very helpful and built the new hoses for the conversion. I opened a 2.5” hole to the right of the existing oil cooler air passage, directed the air with a 2.5” scat tube to a custom plenum that covers the new oil cooler. The new cooler is mounted 3” from the firewall to allow the air to exit easily.

I currently have 15 hours on the mod and have been able to get the oil to 235f by force, flying totally wrong, 85f day, 1 notch flaps, 61 kts, climbing 700fpm for 4000’. As soon as I dropped the nose and hit 85 kts within 2 minutes the oil was 222f and falling. Typically I see 200 – 205f in cruise 5400 RPM, 116 kts, 3500ft. On normal climbs that I would have hit 245f by the time I climbed 3000’ I now can climb continuous to 8000’ and stay under 220f. I will add more flight temperature info when the daily temps get back in the 100’s. The total added weight of the conversion was 2.8 pounds.

UPDATE 7/22/2023

I finally had an extremely HOT day to put the 2nd oil cooler to the test. On the way back to So Cal from Montana I stopped by Hurricane UT. for gas. It was noon and HOT, the plane was at gross. The density altitude was 7300 and my engine was hot from the flight in. On departure the air temp was 104f. I climbed out at 85 – 90 kts continuous to 13,000’ DA. The oil peaked at 225f about 5 minutes into the climb then fell back. Coolant also peaked at 230f and fell back. I kept the throttle at 100% until I reached 13,000 DA. When I leveled off the oil was 201f.

oil cooler – https://www.amazon.com/dp/B0011FPOCM?psc=1&ref=ppx_yo2ov_dt_b_product_details

Oil cooler fittings – https://www.amazon.com/dp/B078CR3V9D?psc=1&ref=ppx_yo2ov_dt_b_product_details

Conductive teflon firesleeved hoses – https://www.aircraftspecialty.com/rv-12.html

I made the oil cooler mount out of .062 aluminum, it supports the oil cooler off the firewall 3”. The plenum was designed using a blue foam core to get the internal shape and alignment for the SCAT tube. Fiberglass and epoxy resin was used for the layup. Another 2 ½ fiberglass tube was made then attached to the lower cowl for the incoming air. The SCAT tube is 2 ½ “ by 12 “.

The following pictures should help explain the process.